Home - Monochloramine Generator – SANIKILL - Sanikill Tec: for large applications

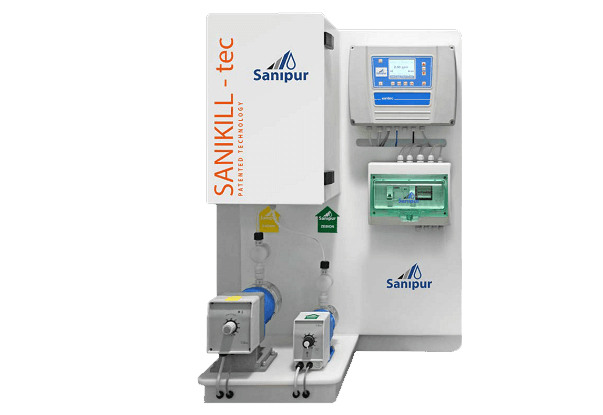

SANIKILL Tec

Monochloramine for large applications

SANIKILL Tec is the version of SANIKILL technology specifically designed for water disinfection through in-line production and dosing of monochloramine for large applications: large buildings, aqueducts, and industrial plants.

Thanks to its high performance and significant production capacity, SANIKILL Tec can effectively disinfect systems with very large water volumes.

Technology

The technological evolution of SANIKILL Tec has been specifically designed to meet the needs of these systems: for this reason, the technology has been optimised to produce monochloramine with maximum efficiency from concentrated precursors (ENOXIN and ZEBION), to reduce storage volumes and refilling operations.

Greater production capacity, without any compromise in terms of precision and accuracy. SANIKILL Tec can ensure finely controlled dosing and operate in three different modes:

- “manual,” to select the desired monochloramine production in g/h.

- “flow rate,” proportional to the flow rate of water to be treated (m3/h) and based on the desired monochloramine concentration value (ppm).

- “flow rate + analysis,” to modulate dosing in “flow rate” mode also based on the ORP value, an indirect measure of the concentration of monochloramine present in the water.

Equipment

SANIKILL Tec is equipped with a remote control and management system that ensures the ability to monitor and modify operating parameters at any time, 24/7, and from any device.

Safety systems

- flow sensors, to verify the correct dosing of precursors;

- level sensors, indicating minimum and empty precursor levels;

- flow control, with the interruption of monochloramine production in the absence of water;

- pH measurement probe, to verify the correct progress of the reaction;

- ORP measurement probe, for monitoring disinfectant dosing and feedback regulation;

- real-time notifications, with alarm alerts sent via email or SMS.

SANIKILL Tec:

Production Capacity

The various models of SANIKILL Tec ensure a production capacity from 500 g/h to 10 kg/h, depending on the specific needs in terms of the required monochloramine dosage and the volume of water to be treated.

To ensure an additional level of flexibility, besides the standard configuration with a single dosing point, SANIKILL Tec also offers a multi-dosing point option, ideal for managing separate water systems with a single disinfection system.

Tec is the ideal solution to ensure adequate water disinfection in systems with large volumes to treat, such as:

- cold and hot sanitary water circuits of large buildings

- water supply networks

- industrial, process, or cooling plants

SANIKILL Tec: technical specifications

| Maximum Monochloramine Production Range | 500 g/h – 10 kg/h |

| Maximum Operating Temperature | 60° C |

| Maximum Operating Pressure | up to 7 bar |

| Electronic Control Unit | IP55 |

| Dimensions | 1050x850x390 mm |

| Power Consumption | 220 Vac 50Hz |

| Power Consumption | Max 500 W |

| Materials | Standard: C-PVC |

| Reagents to Use | Enoxin P15 Plus e Zebion P35B/Zebion P35DW |